REVOLUTIONIZING MANUFACTURING

WITH AUTOMATED MICROFACTORIES.

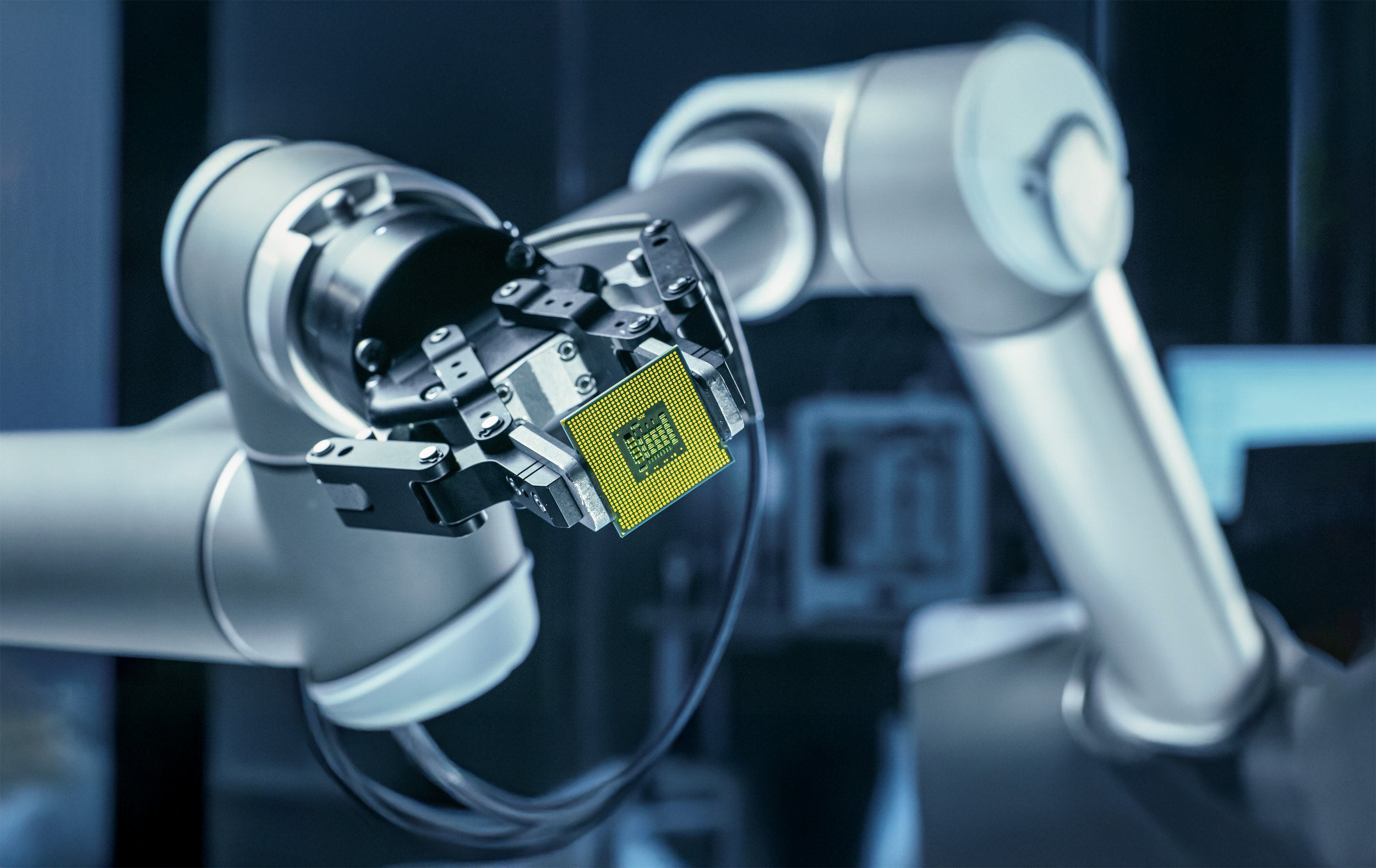

At Aspired, we are pioneering the future of manufacturing by developing automated microfactories that transform how products are made – on-demand, in smaller batches, and closer to the consumer - while harnessing the power of automation, robotics, and cloud-edge computing to optimize every step of the process.

HERE'S HOW IMPLEMENTING MICROFACTORIES CAN TRANSFORM YOUR OPERATIONS:

PRODUCTIVITY INCREASE

The integration of AI and automation into microfactories can boost productivity by 15-30% (World Economic Forum, 2024). The modular design of microfactories allows for simultaneous execution of multiple tasks, which accelerates production cycles and reduces idle time. This flexibility leads to faster, more efficient manufacturing processes. Additionally, cloud-edge computing solutions can reduce system downtime by 35% (Tekvaly, 2024), further enhancing overall productivity.

COST REDUCTION

Microfactories can reduce manufacturing costs significantly due to their smaller scale, lower energy consumption, and reduced labor requirements. High levels of automation and AI technology enable more efficient operations and the ability to implement changes without significantly increasing costs. Some microfactories use up to 90% less water, up to 50% fewer chemicals, and up to 80% less energy than traditional factories (World Economic Forum, 2024), contributing to cost reductions.

REDUCED CARBON FOOTPRINT

By localizing production and reducing the need for long-distance transportation, microfactories can lower their carbon footprint by up to 67% (Gelato, 2024). This is a crucial benefit for companies aiming to improve sustainability and reduce their environmental impact. The ability to produce goods closer to the end consumer not only cuts down on transportation emissions but also decreases packaging waste. Decentralized manufacturing can also reduce transport and logistics costs by 18% while enabling a 22% faster order fulfillment time (Robert Ziner MBA, 2024).

ENERGY SAVINGS

Microfactories typically consume 20-80% less energy (World Economic Forum, 2024) compared to conventional manufacturing plants. This is primarily due to their smaller physical footprint and the use of energy-efficient technologies, such as optimized lighting, automated machinery, and advanced cooling systems. AI-driven HVAC (heating, ventilation, and air conditioning) systems can further reduce energy costs by 20-73% (Applied Thermal Engineering, 2023), optimizing climate control and energy usage.

FASTER TIME-TO-MARKET

The microfactory model enables companies to shorten their time-to-market by up to 22% (Robert Ziner MBA, 2024). This speed advantage is achieved by providing rapid reconfigurations of production lines, allowing manufacturers to quickly adapt to changing market demands or customer preferences. Cloud-edge computing solutions further enhance this efficiency by reducing latency by up to 90% (The Quantum Zeitgeist, 2024), ensuring real-time decision-making and seamless production adjustments.

ENHANCED SYSTEM RELIABILITY

The implementation of cloud edge computing can reduce system downtime in the event of network outages by 35% and reduce latency to less than 5 milliseconds, compared to 20-40 milliseconds for cloud-based computing (Tekvaly, 2024). This ensures higher operational efficiency and resilience in automated production environments.

WHY CHOOSE MICROFACTORIES FOR YOUR BUSINESS?

By integrating automation, robotics, and energy-efficient technologies, the microfactory systems provide faster, smarter, and more cost-effective ways to produce high-quality products. As industries continue to evolve, the future of manufacturing lies in smaller, more agile, and sustainable production methods - and microfactories are leading the charge.

LET’S WORK TOGETHER

Reach out to us to explore how we can work together to create microfactories tailored to your specific needs and business goals.

Aspired SIA

Toms Vācietis

+371 29 476 782

toms.vacietis@aspired.lv

NEXTGEN MICROFACTORIES

January 1, 2025, to December 31, 2027

Project "Nextgen Microfactories" focuses on developing smart, highly automated microfactories by integrating cloud-edge computing and AI-driven robotics. The project aims to improve manufacturing efficiency and sustainability, reducing reliance on non-European cloud service providers.

By developing and testing cloud-edge solutions for mobile robotics, industrial automation, and decentralized production, the project contributes to the transition towards Industry 5.0. These innovations will help optimize production processes, reduce operational costs, and support the development of energy-efficient manufacturing ecosystems.

OUR PARTNERS

PROJEKTA ATSKATS

-

Ceturtdien, 14. augustā, notiks jauna projekta "Nextgen Microfactories" jeb "Nākamās paaudzes mikroražotnes" atklāšana.

Šis projekts ir daļa no Eiropas programmas - Eiropai svarīgo kopīgo interešu projektu (IPCEI) iniciatīva - kuras mērķis ir atbalstīt jaunu tehnoloģiju izpēti, izmēģināšanu un ieviešanu.

Ko tas nozīmē? Projekta ideja ir attīstī gudras, ļoti automatizētas maza izmēra ražotnes. Tās izmantos mākoņdatošanu un mākslīgā intelekta vadītus robotus, lai strādātu efektīvāk un videi draudzīgāk. Vēl viens mērķis — lai Eiropas uzņēmumi būtu mazāk atkarīgi no ārpus Eiropas esošiem mākoņpakalpojumu sniedzējiem.

Ko darīsim?

Veidosim risinājumus robotiem, kas strādā, izmantojot lokālo mākoņdatu apstrādi.

Attīstīsim rūpniecisko automatizāciju.

Izstrādāsim sistēmas decentralizētai (daudzās vietās izkliedētai) ražošanai.

Radīsim gudru industriālo ēku vadības sistēmas.

Projektu "Nextgen Microfactories" īsteno tehnoloģiju uzņēmumi, sadarbojoties SIA Aspired ar projekta partneriem — SIA TestDevLab, Ventspils Augsto tehnoloģiju parks (VATP), SIA Dati Group, SIA TechGym, SIA Asya un SIA Natrix. Projektā piedalās arī līgumslēdzēji no trīs ES dalībvalstīm, kuri īsteno savus IPCEI-CIS projektus: Siemens AG (Vācija), Engineering Ingegneria Informatica S.p.A. (Itālija), SIA Tilde (Latvija).

Projekta īstenošanas līgums parakstīts šī gada 30. jūnijā un tā aktivitātes norisināsies līdz 2027. gada beigām. Kopējās izmaksas — 7,4 miljoni eiro, no kuriem 5,57 miljonus sedz Eiropas Atveseļošanas un noturības mehānisms.

Informācija uzziņai

Projekts tiek īstenots Eiropai svarīgo kopīgo interešu projektu (IPCEI) iniciatīvas ietvaros. Iniciatīvas mērķis ir atbalsīt jaunu programmatūru un tehnoloģiju pētījumus, eksperimentālo izstrādi un ieviešanas pilotprojektus Eiropā.

Projekts "Nextgen Microfactories" ir vērsts uz gudru, augsti automatizētu mikroražotņu izstrādi, integrējot mākoņdatošanas tehnoloģiju un mākslīgā intelekta vadītu robotiku.

Projekta mērķis ir uzlabot ražošanas efektivitāti un ilgtspēju, samazinot atkarību no mākoņpakalpojumu sniedzējiem, kas nav Eiropas mākoņpakalpojumu sniedzēji.

Izstrādājot un testējot mākoņmodernus risinājumus mobilajai robotikai, rūpnieciskajai automatizācijai un decentralizētai ražošanai, projekts sekmē pāreju uz Rūpniecību 5.0. Šīs

inovācijas palīdzēs optimizēt ražošanas procesus, samazināt darbības izmaksas un atbalstīt energoefektīvu ražošanas ekosistēmu attīstību.

Projekta ietvaros tiks īstenoti četri galvenie darba virzieni: mobilo robotu mākoņmalas risinājumi, rūpnieciskās ražošanas mākoņmala, decentralizētā ražošana un dizaina sistēma, viedo industriālo ēku mākoņmala.